Installation Guide

1.Ask the customer to count the number of flooring and accessories signed for.

2.Check the dryness and flatness of the floor, if it does not meet the installation requirements, point out and explain to the customer, and reconfirm the installation time with the installation department and the customer.

3.Installation tools should be held lightly, if it is a power tool should be used to prevent damage to the floor with the closure.

4.The installation should be done in such a way as to minimize the cost of using the flooring. Completion 1 Organize the installation tools and clean the floor.

5.Organize excess flooring and accessories, ask the customer to count and sign for them, and settle the balance.

6.Inform the customer of the following precautions a Minimize walking on the floor within 24 hours. b Move heavy objects only after 48 hours. 4 Give the customer a quality guarantee card and explain it to the customer.

Installation process design ground preparation

1、The ground for installing the floor needs special preparation. For every 1 square meter of ground, the unevenness is allowed to be 2㎜ at most, and the ground should be made first and then installed.

2、The base floor must be dry.

3. The floor should be laid in a "floating" way, and if it is laid on a felt floor, it does not need any padding. If laying on the cement ground, you must first lay a layer of 2-3㎜ thick special PE moisture-proof layer, the moisture-proof layer and the moisture-proof layer should be sealed with tape along 1 wall to prevent the ground moisture leakage, affecting the floor leveling, the moisture-proof layer is mainly to prevent the ground from moisture leakage and trimming the ground bumps and bumps, so that the floor has elasticity and maintains the effect of leveling and soundproofing.

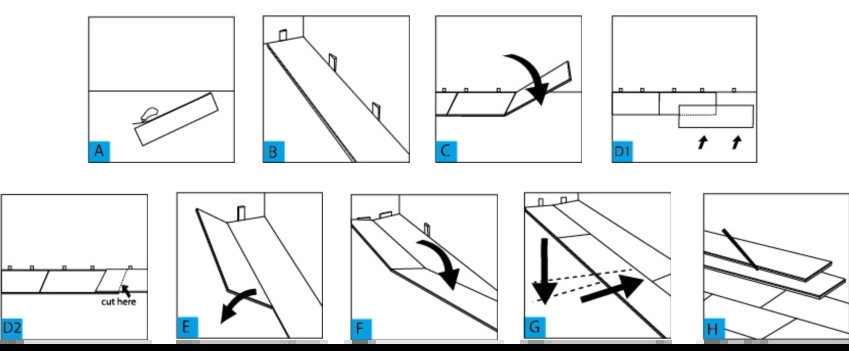

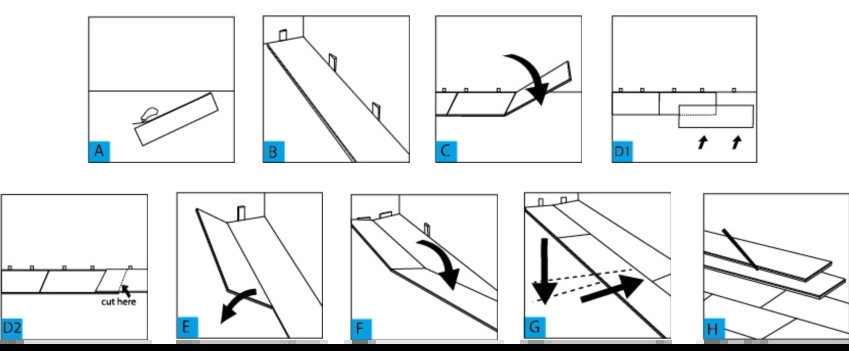

Installation procedure

1、Use the special tools for installing laminate flooring.

2, laying the first floor, from left to right order of laying, the enterprise notch to the wall wedged into the pad to prevent expansion, to be installed after the end of all, before removing.

3, the beginning of the process of the first two, three acts of test paving, and do not apply glue, formal paving and then apply glue, if the edge of the wall is not straight, according to the edge of the wall contour line.

4, paving the last piece of the first row when measuring its size (pay attention to leave the distance of the wedge), and then use a saw to saw off the excess.

5、The length of the remaining part of the last piece of the first row can be used as the first piece of the second row if it is longer than 40cm, and the first two rows must be laid safely and parallel.

6, the first and second line of the glue is basically cured (about two hours) the continuation of the line of the floor began to lay, should try to ensure that the laying of straight.

7, there are special boards and hammers to make the connection between the floor tight, the operation should be very careful.

8, laying the last piece of flooring should be placed on top of the last row, tongue and groove towards the wall, before sawing off should ensure that the scribing line is accurate. 9 with special hooks to the last row of flooring installation in place, pay attention to the wall and the floor between the head of the wooden wedge.

9, the floor paving 24 hours after taking off the wooden wedge, with skirting line to cover off the floor and the wall between the gap, and make sure the floor is floating state, its expansion and contraction can not be limited.